|

|

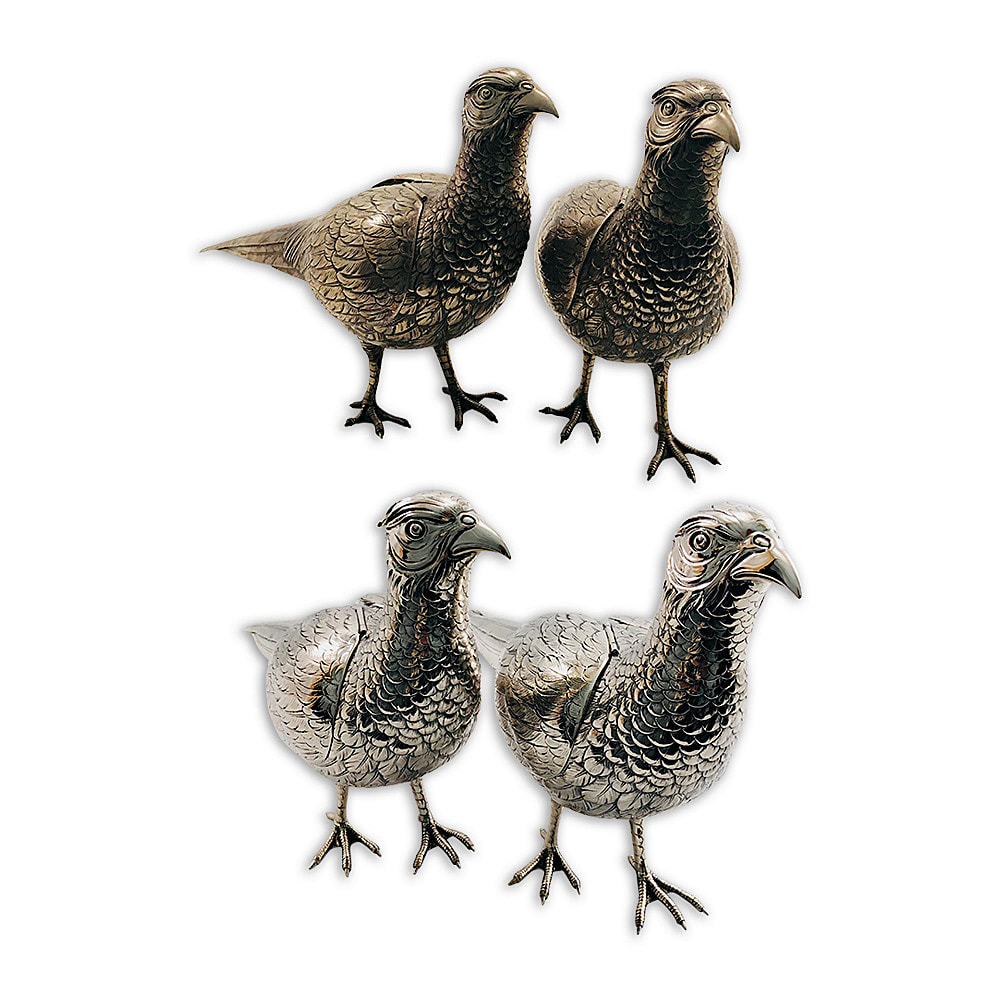

SILVER PLATING AND RESTORATION SERVICESChelsea Plating Company offers specialized services in silver plating, repair, and restoration, bringing back the elegance of sterling silver and silverplate items. Our experienced craftsmen provide a comprehensive range of services, including cleaning, polishing, re-silvering, and repairing antiques and heirlooms. We focus on preserving both the aesthetic and historical value of your silverware, ensuring each piece returns to you with renewed luster and integrity. Using refined cleaning methods to remove tarnish and surface impurities, we meticulously polish and re-silver items to ensure a durable and elegant finish. Our skilled silversmiths employ techniques such as soldering and planishing to repair and strengthen silverware, maintaining a commitment to quality craftsmanship and attention to detail. Trust us to handle your cherished silver items with the utmost care, providing results that exceed your expectations and restore timeless elegance to your collection.

|

STERLING SILVER AND SILVERPLATE REPAIR AND POLISHINGAt Chelsea Plating Company, we provide expert repair, cleaning, and polishing services for sterling silver and silverplate items. Our meticulous process includes detailed restoration to ensure every piece, from antique silverware to contemporary silver items, regains its original brilliance and texture. Specializing in silver restoration, we use effective methods to revive tarnished and worn silver items. Our restoration process begins with a thorough inspection to identify any damage, wear, or tarnish, followed by careful cleaning and polishing using refined techniques and tools. We address issues such as dents, scratches, and structural damage to ensure your silver items are not only beautiful but also functional. For antique silverware, we preserve historical and sentimental value through traditional methods, restoring heirlooms to their former glory without compromising authenticity. Additionally, we provide preventative care advice for maintaining the beauty of your silver at home. At Chelsea Plating Company, customer satisfaction is our top priority, and we are dedicated to delivering exceptional results, ensuring your silver items are restored to their highest quality. Whether you have a cherished family heirloom or a contemporary silver piece, trust us to bring back its brilliance and elegance.

|

SILVER PLATING AND RE-SILVERING ANTIQUESOur silver plating, or 're-silvering', services cater to antique heirlooms, restoring their timeless beauty. We apply traditional 'silver dipping' methods combined with precision to ensure a durable and elegant finish on each piece, preserving its historical value. Our process begins with a careful assessment of each item to understand its unique characteristics and requirements. We then meticulously prepare the surface, removing any tarnish or imperfections, to create a pristine base for the silver plating. By using high-quality materials and skilled craftsmanship, we ensure that the re-silvered items not only regain their original luster but also maintain their integrity and durability over time. At Chelsea Plating Company, we take pride in our ability to blend traditional techniques with meticulous attention to detail, resulting in beautifully restored heirlooms that can be cherished for generations. Trust us to preserve the elegance and historical significance of your antique silver items through our dedicated silver plating and re-silvering services.

|

MONOGRAM AND ENGRAVING REMOVAL SERVICESWe specialize in the delicate removal of monograms and engravings from silver items. Our skilled artisans carefully erase unwanted inscriptions, restoring the smooth surface of your silver pieces while maintaining their integrity and design. Each piece is meticulously examined to determine the best approach for removing the engravings without compromising the item's structural integrity. We use refined techniques to blend the treated areas seamlessly with the original surface, ensuring that no trace of the previous markings remains. This process not only enhances the appearance of your silver items but also prepares them for new customizations if desired. At Chelsea Plating Company, we take pride in our attention to detail and commitment to preserving the craftsmanship of your valuable silver pieces. Trust us to return your silver items to their original, unmarked beauty while retaining their elegance and historical value.

|

DENT AND SCRATCH REMOVAL FOR SILVERWAREOur expertise in dent and scratch removal transforms damaged silverware into immaculate pieces. We address every imperfection with precision, restoring the aesthetic appeal and structural integrity of your cherished silver items. Each item undergoes a thorough inspection to identify all dents, scratches, and other blemishes. Our skilled silversmiths use techniques such as planishing to smooth out dents and burnishing to remove fine scratches, ensuring that the restored silverware looks as pristine as the day it was made. For deeper scratches, we employ a delicate polishing process to blend the repaired areas seamlessly with the original surface. Whether it's a treasured family heirloom or a valuable antique, we handle each piece with the utmost care, preserving its original craftsmanship and beauty. At Chelsea Plating Company, our commitment to excellence guarantees that your silverware will be returned to you in impeccable condition, ready to be admired and used with pride.

|

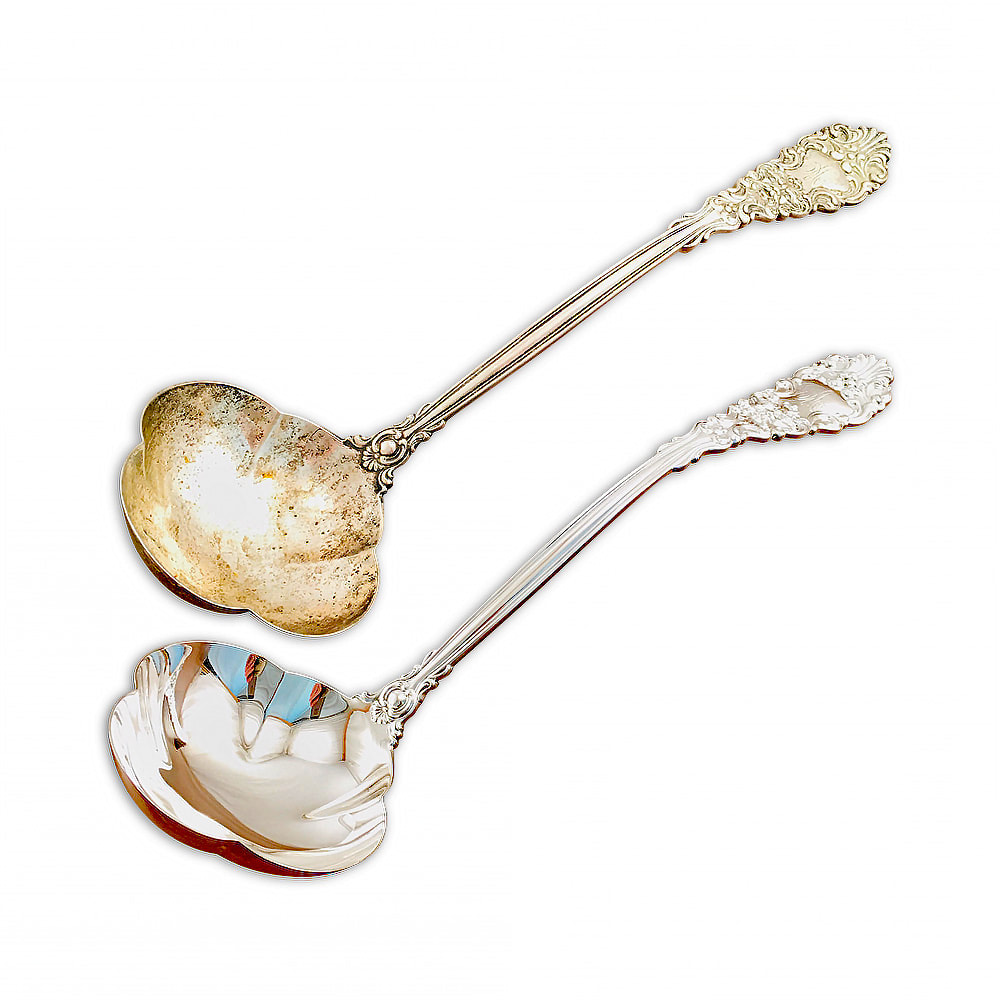

FLATWARE RESTORATION: STERLING SILVER AND SILVERPLATEWe excel in the restoration of sterling silver and silverplate flatware, from individual forks and spoons to complete sets. Our comprehensive restoration process ensures each piece is returned to its pristine condition, ready for both display and use. Our process begins with a detailed assessment of each item to identify areas of wear, damage, and tarnish. We then employ specialized cleaning methods to remove surface dirt and oxidation, followed by meticulous polishing to restore the flatware's original luster. For pieces with more significant damage, such as bent tines or handles, our skilled silversmiths use techniques like annealing to soften the metal and carefully reshape it to its original form. We also address issues such as loose knife blades by securely resetting them, ensuring the flatware is both beautiful and functional. Our final step includes a protective coating to prevent future tarnish, maintaining the restored condition for years to come. At Chelsea Plating Company, we take pride in our attention to detail and commitment to preserving the historical and aesthetic value of your flatware, making it ready to grace your dining table or be displayed as a treasured heirloom.

|

REPAIRING DISPOSAL DAMAGE TO SILVER FLATWAREOur services include repairing disposal damage to silver flatware, effectively addressing scratches, chips, bends, and other damage caused by disposal units. We restore the functionality and beauty of your flatware, ensuring it remains a valuable part of your dining experience. Our process begins with a careful inspection to assess the extent of the damage. For scratches and chips, we use fine abrasives and polishing techniques to smooth and blend the affected areas seamlessly with the rest of the piece. Bent tines or handles are gently straightened using precise annealing methods, which involve heating the metal to make it pliable and then carefully reshaping it. In cases where the flatware is significantly damaged, our skilled silversmiths may employ soldering to repair broken or cracked parts, ensuring a strong and durable fix. Once the structural repairs are completed, we meticulously polish each piece to restore its original shine and luster. At Chelsea Plating Company, we understand the sentimental and practical value of your silver flatware, and we are dedicated to bringing it back to its best condition. Trust us to handle your damaged flatware with the utmost care, so it continues to enhance your dining table with its elegance and functionality.

|

KNIFE BLADE RESET AND REPLACEMENTWe provide knife blade resetting and replacement services, essential for maintaining the quality and usability of your silver cutlery. Whether resetting a loosened blade or replacing a damaged one, we ensure your knives are in top condition. Our process begins with a thorough examination of the knife to determine the best course of action. For blades that have become loose over time, we carefully disassemble the knife, clean the components, and securely reset the blade into the handle, ensuring a tight and stable fit. In cases where the blade is damaged beyond repair, we source high-quality replacement blades that match the original in style and size. Our skilled craftsmen then meticulously fit the new blade, ensuring seamless integration with the existing handle. Throughout the process, we take great care to preserve the aesthetic and historical integrity of the knife, paying attention to every detail. Once the blade is securely in place, we perform a final polishing to restore the overall appearance of the knife. At Chelsea Plating Company, we are dedicated to providing top-notch knife restoration services, ensuring your silver cutlery remains both functional and beautiful for years to come.

|